Hydraulic Lifts for the Modern Commercial Vehicle Workshop

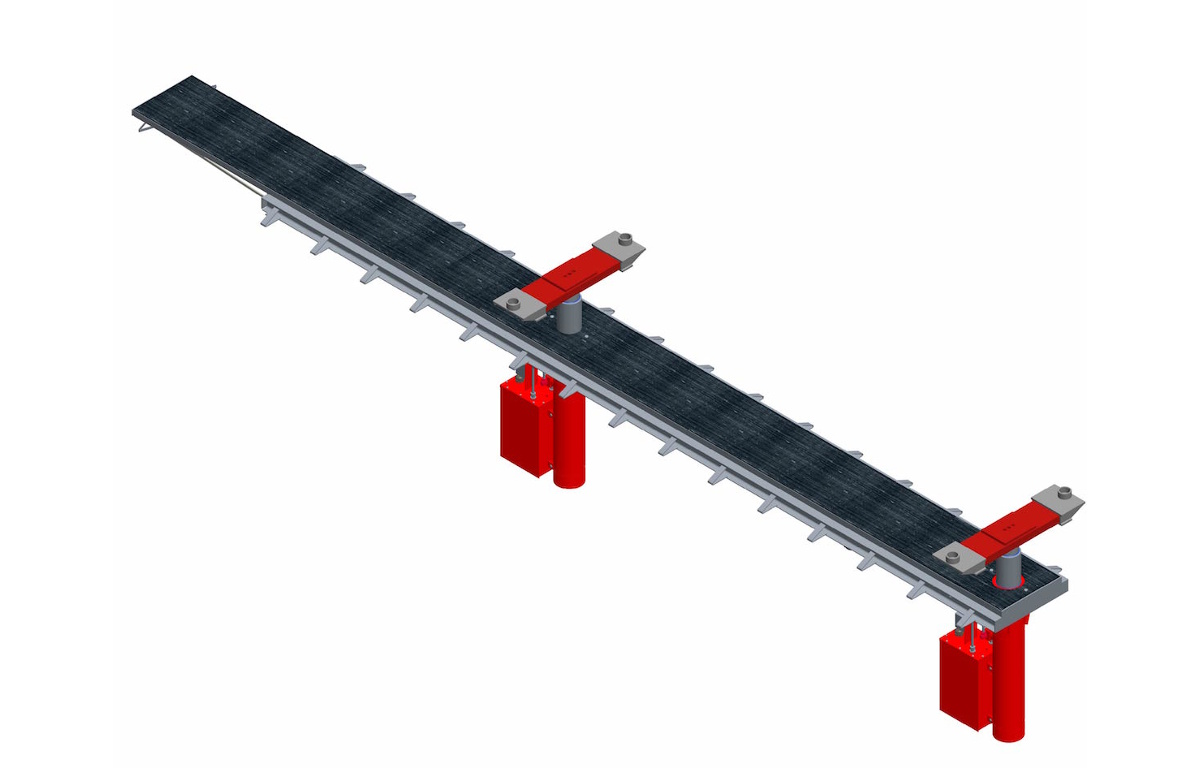

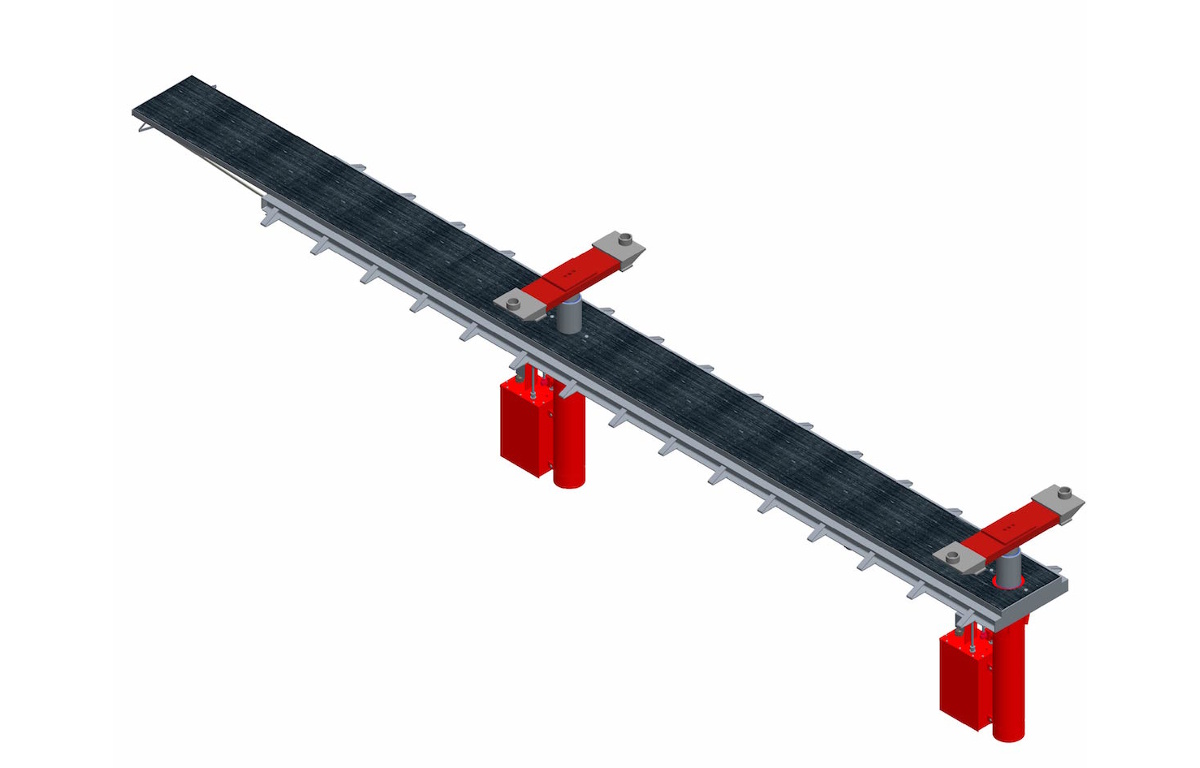

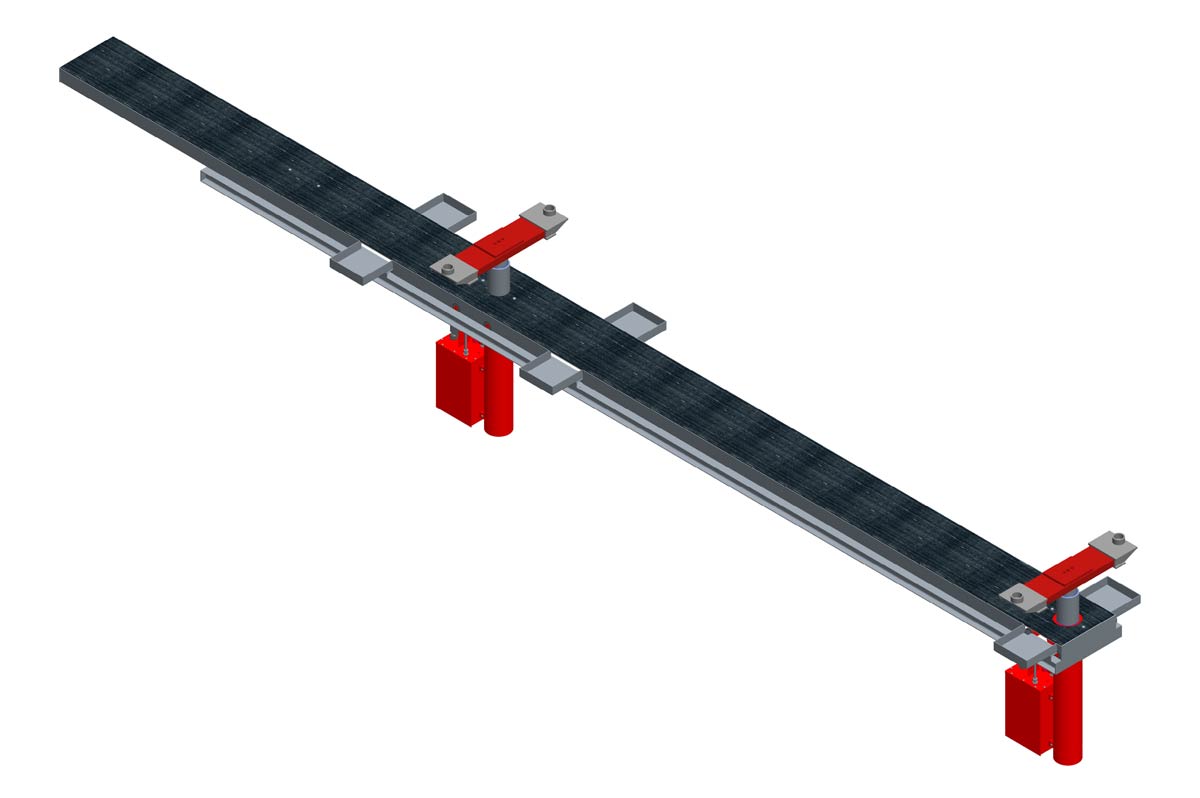

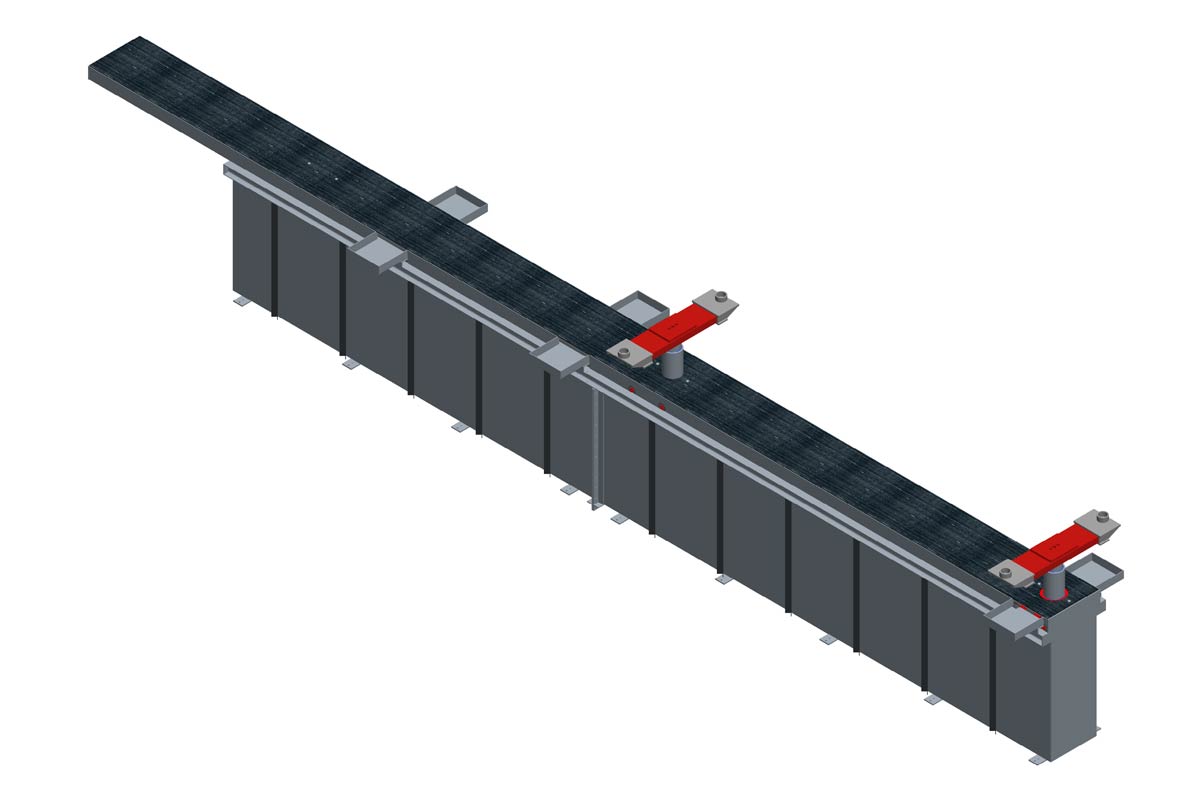

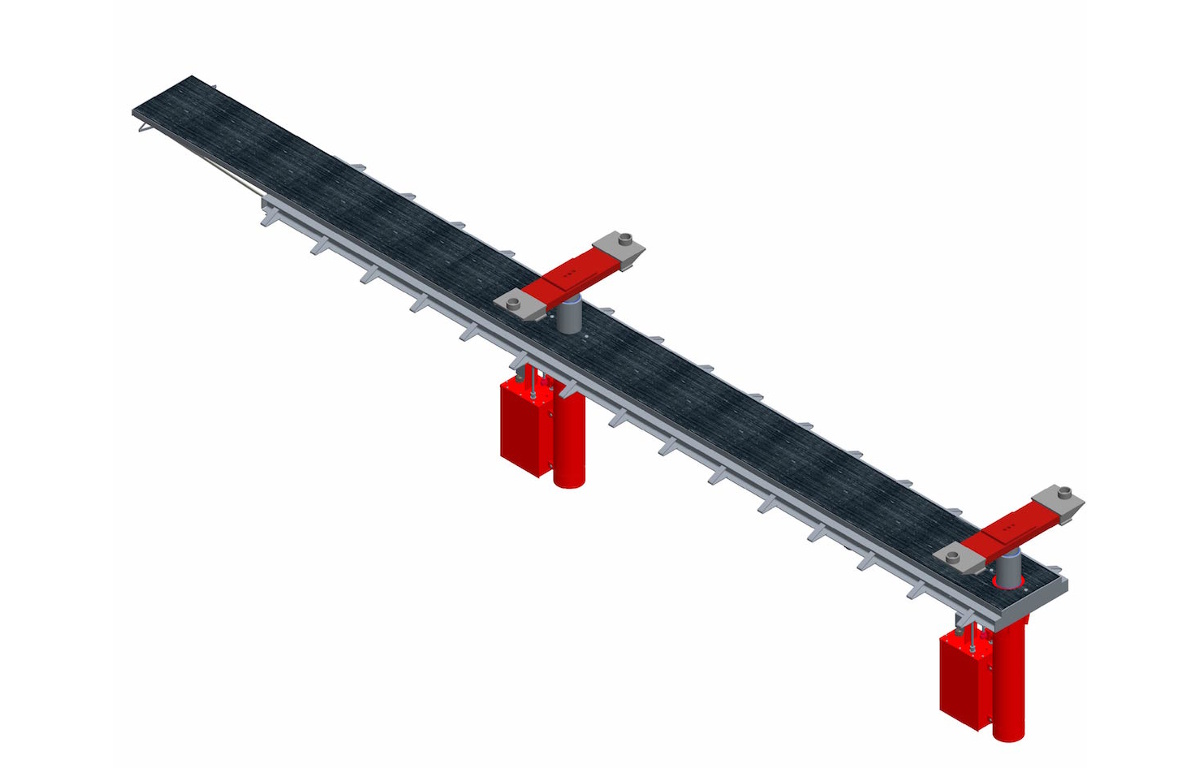

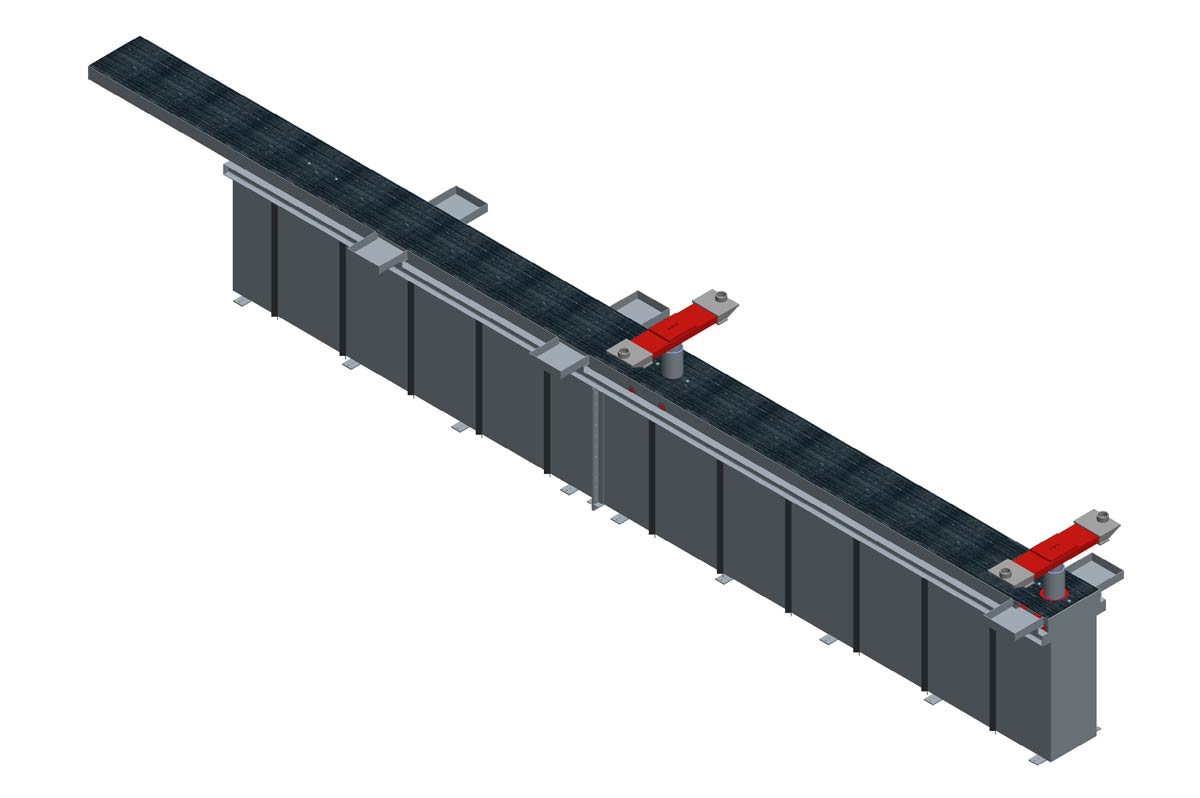

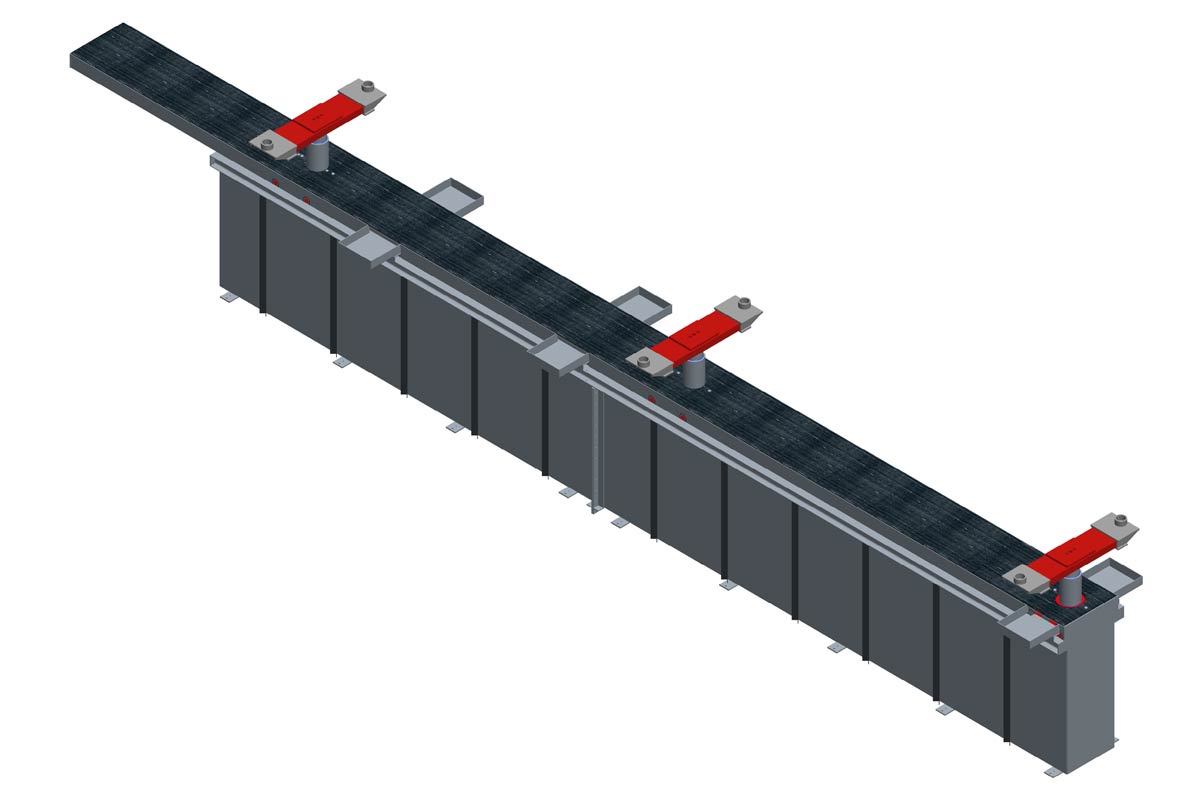

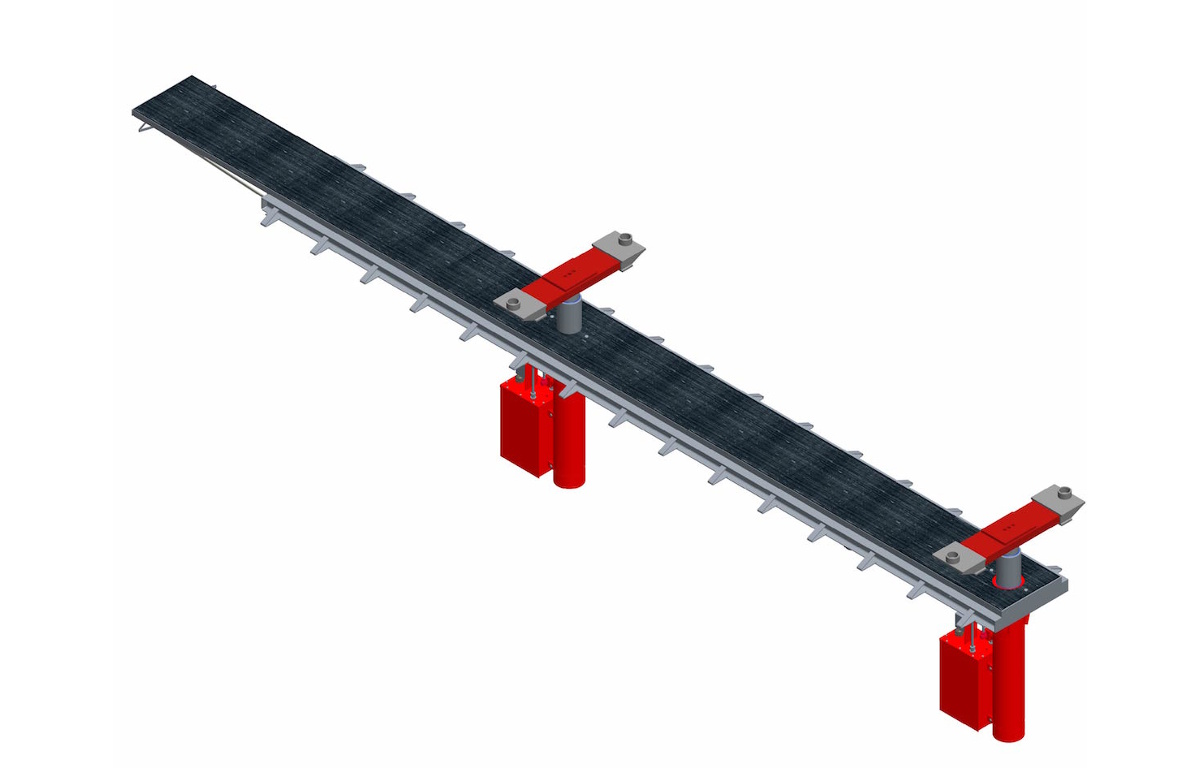

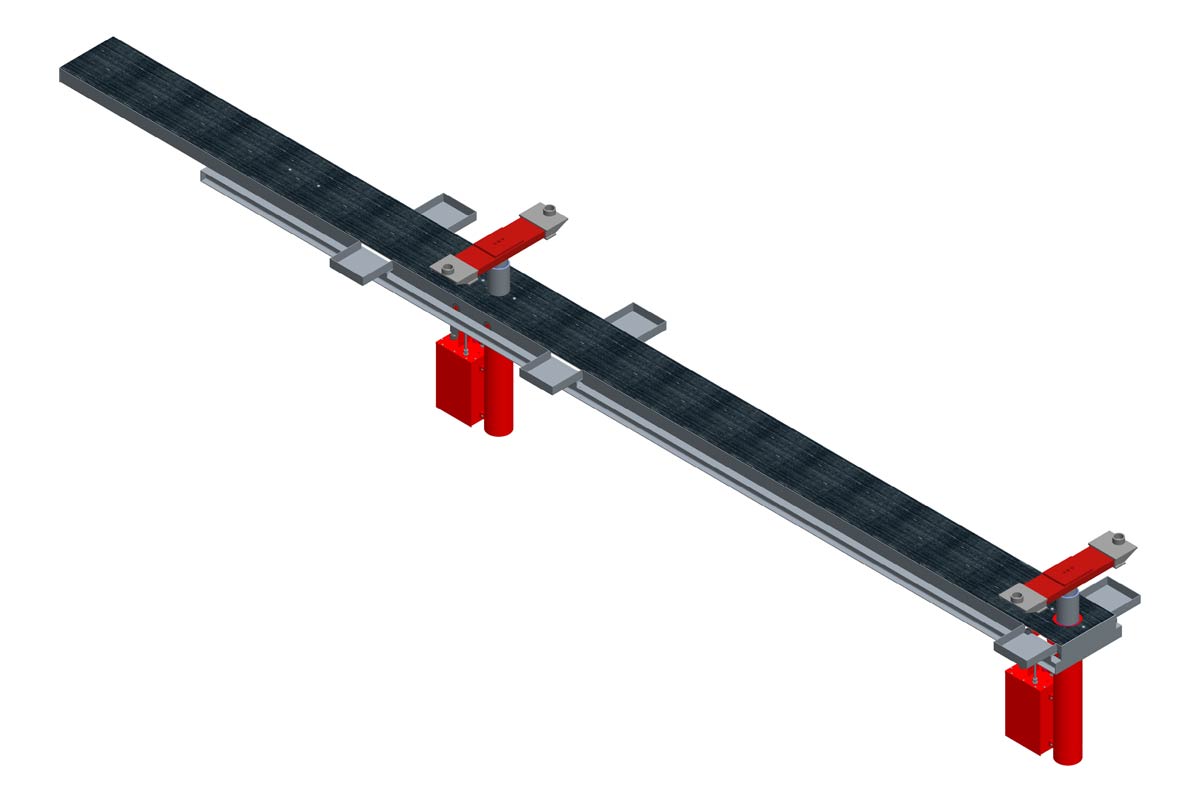

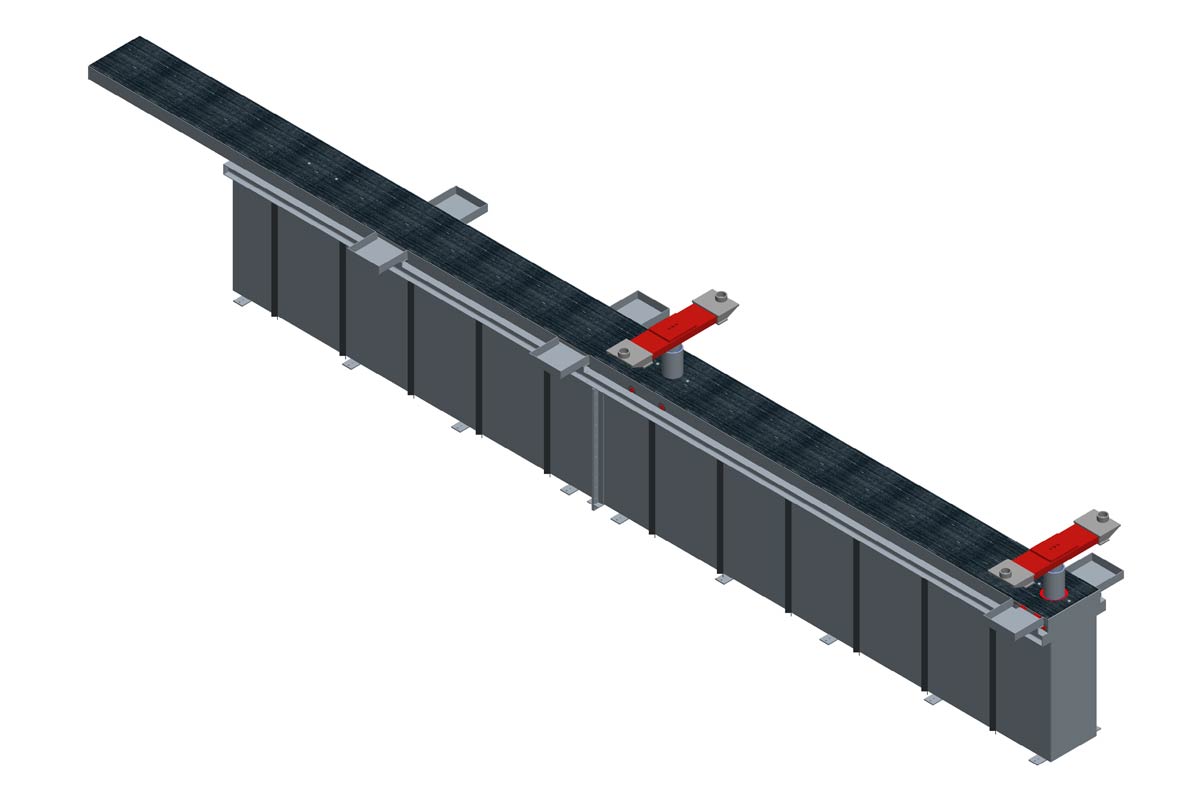

Fuchs Hydraulik manufactures electro-hydraulic cylinder lifts for modern commercial vehicle workshops. Our lifts keep the vehicle wheels free and are suitable for all common repair and maintenance work on commercial vehicles and buses. The lifts are available with either one piece or telescopic pistons. Both types can be installed using a fame fitted above a concrete pit or using a steel trough. A variety of lifting capacities is available and is dependent on the number of rams used. Standard lifts reach an of 1700mm, there is also a short stroke version available for tyre service areas, this has a stroke of 700mm. As a German company with headquarters and production in Rhineland-Palatinate, with our lifts we stand for quality “Made in Germany”.

Quality and Safety

Fuchs Hydraulik lifts are TÜV Rheinland EC type-approved. Developed over many years, our lifts ensure reliable and safe operation through a specially developed valve system, hard chromed pistons and special piston guides. The optimum working position is set by pressing a button. Fuchs Hydraulik lifts are very low-maintenance and durable. De

Easy operation

Fuchs lifts feature rotatable support beams which, combined with the supplied adapters, lifts the vehicle on its axles. This gives excellent visibility under the vehicle, allows access to all parts including the wheels. The lifts are particularly suited to the removal of heavy components like engines or gearboxes. The rams are positioned under the axles using a motorised drive and the pit remains covered by the telescopic cover system which can carry loads up to 5t.

Models and Installation

Fuchs lifts are simple to install once any groundworks are completed. They can also be retrofitted to existing frames or inspection pits. Versions are available for wash bays, spray booths and explosive environments. Bespoke designs are available for special circumstances.

Features

EC type-tested · Made in Germany · low maintenance · robust and long-lasting · pivoting support beam · specially developed in-house non-return valve system · vehicles are freely accessible from all sides without additional support systems · easy installation · retrofitting also possible · powered positioning of the cylinder units · automatic sliding of the telescopic pit cover in sliding sheet design · special customised constructions available

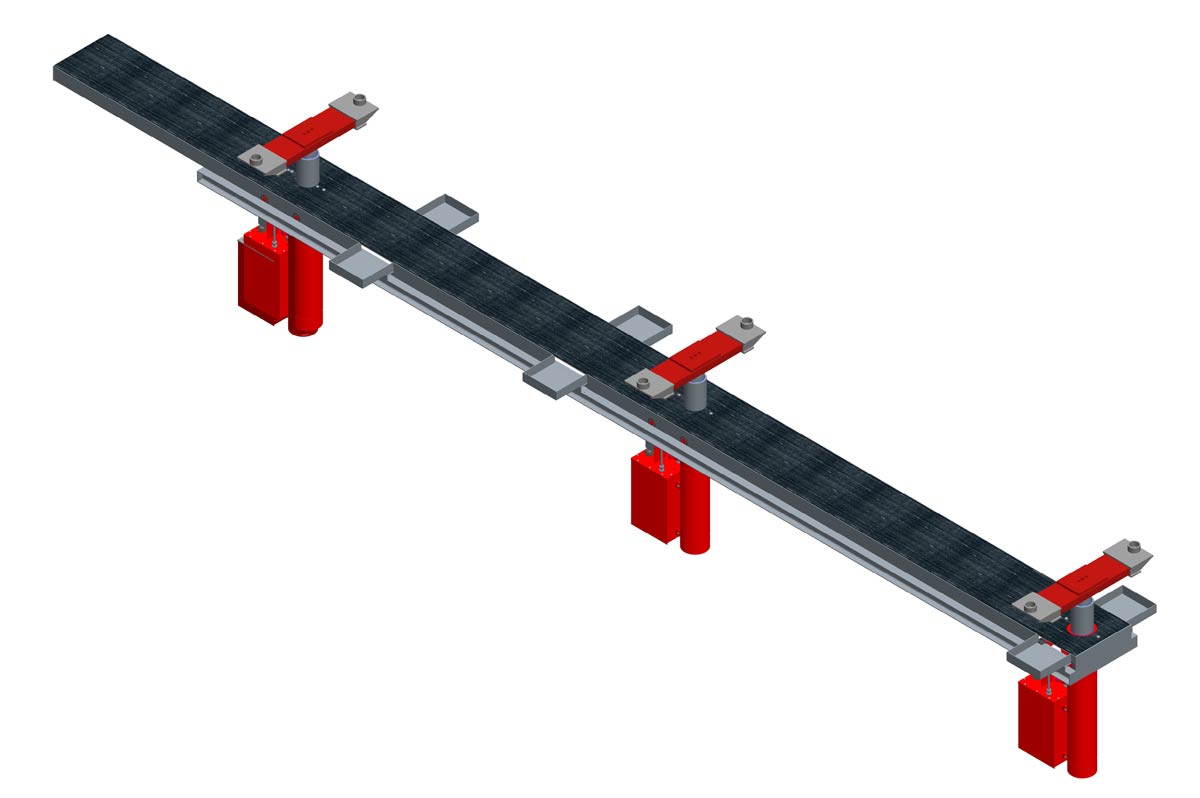

One-piece cylinders

KAE 10/2-B

- Model: KAE 10/2-B //// B = concrete pit

- Model: KAE 10/2-B-VR //// B-VR = concrete pit with frame and sunken support beams including roller covers

- Model: KAE 10/2-W-VR //// W-VR = trough pit with frame and sunken support beams including roller covers

| Cylinders | 2 |

| Capacity | 2 x 14t |

| Stroke | 700mm |

| Piston Ø | 120mm |

| Mounting depth | 1200mm |

| Frame length | 7000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 2,5m – max 6,5m |

| Art.-No. | 8.224.000 |

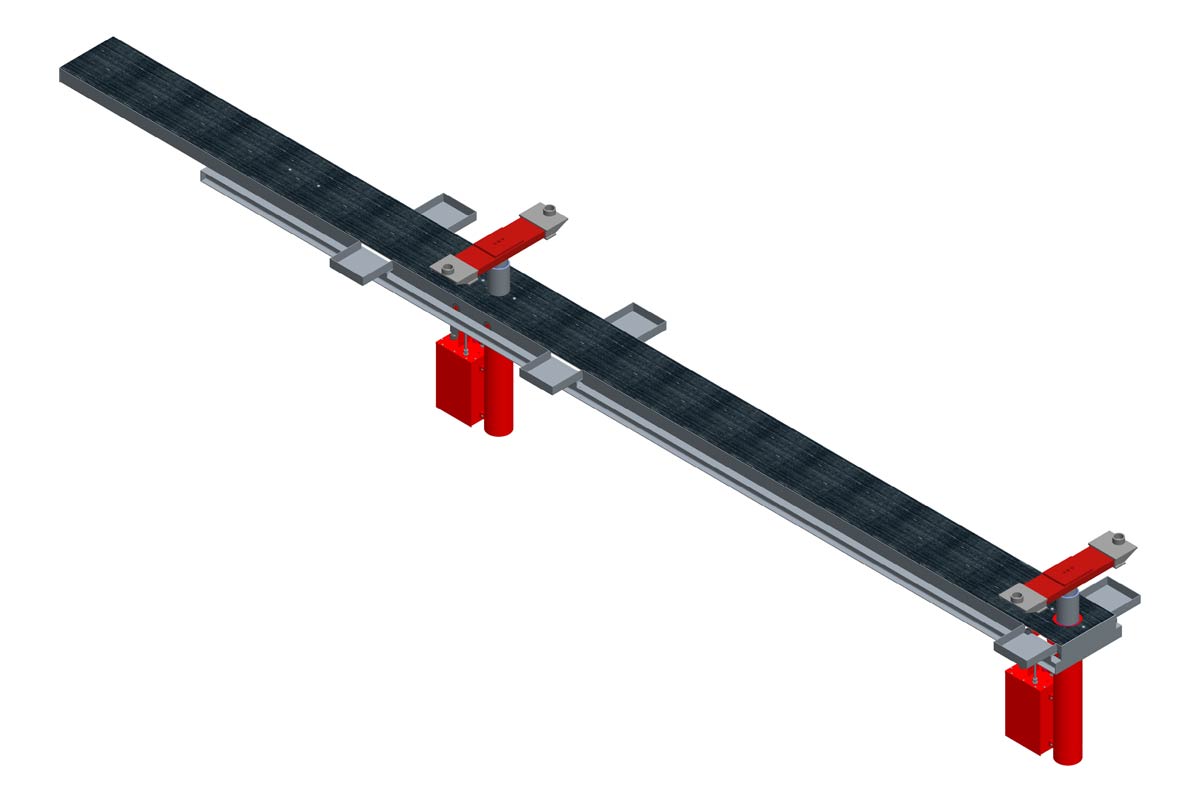

ST 10/2-B

- Model: ST 10/2-B //// B = concrete pit

- Model: ST 10/2-B-VR //// concrete pit with frame and sunken support beams including roller covers

| Cylinders | 2 |

| Capacity | 2 x 14t |

| Stroke | 1700mm |

| Piston Ø | 150mm |

| Mounting depth | 2200mm |

| Frame length | 7000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 2,5m – max 6,5m |

| Art.-No. | 8.223.000 |

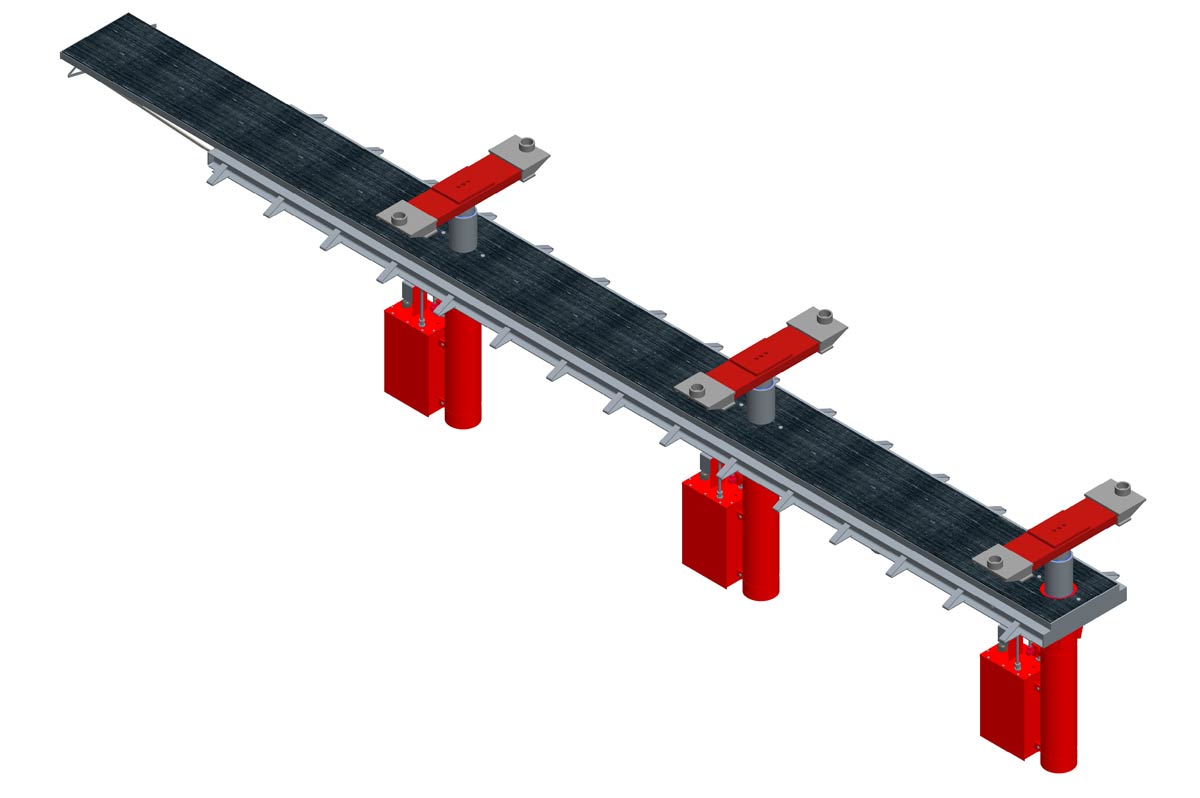

ST 10/3-B

- Model: ST 10/3-B //// B = concrete pit

- Model: ST 10/3-B-VR //// B-VR = concrete pit with frame and sunken support beams including roller covers

| Cylinders | 3 |

| Capacity | 3 x 14t |

| Stroke | 1700mm |

| Piston Ø | 150mm |

| Mounting depth | 2200mm |

| Frame length | 7000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 2,5m – max 6,5m |

| Art.-No. | 8.195.008 |

Options

- Combination of units in one frame. Example: 4 cylinders 2+2 or 3+1

- Wash bay version (7m): axles, rollers, flashings and accessories galvanised, switch cabinet heated

- B = concrete pit

- W = trough version in the pit

- B-VR= concrete pit with frame and sunken support beams including roller covers

- W-VR= trough pit with frame and sunken support beams including roller covers

- Galvanised

- Telescopic cover 5t (15mm)

- Galvanised ground frame.

- Extensions to ground frames, covering and adjustment of the lift units

Telescopic cylinders

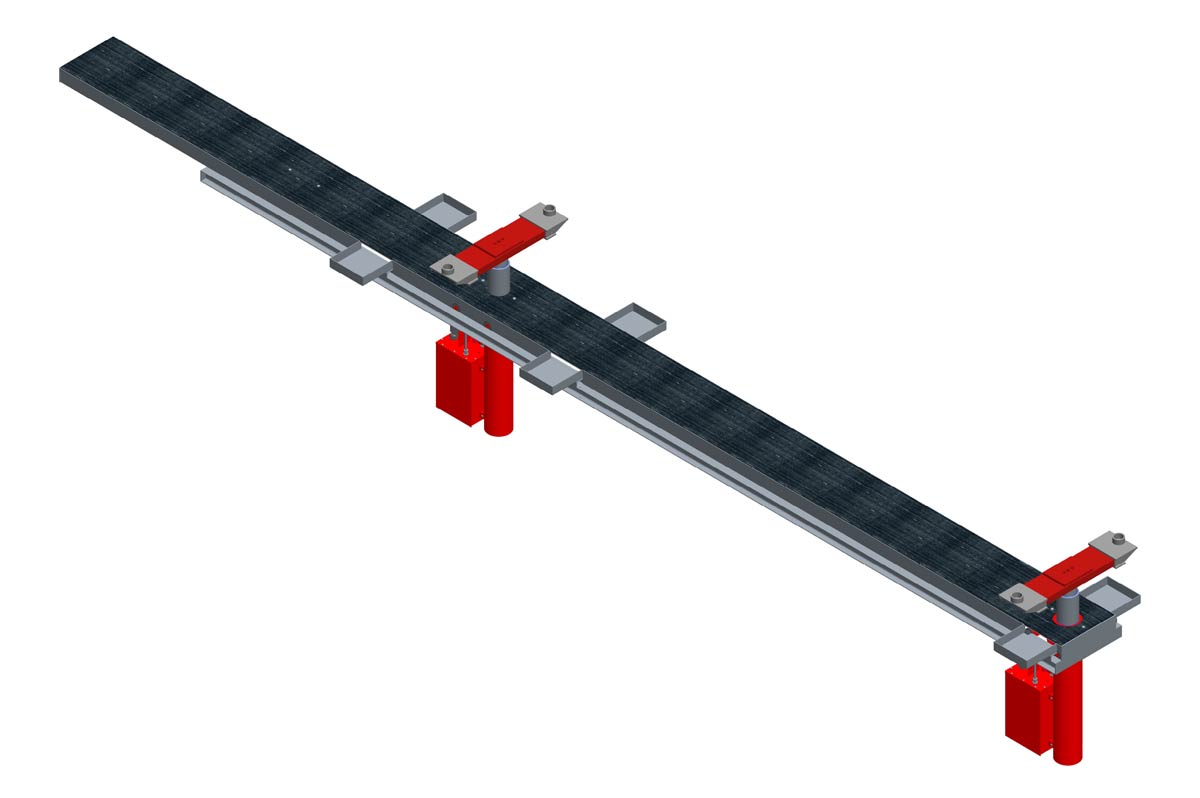

TH 5/2-B

- Model: TH 5/2-B //// B = concrete pit

- Model: TH 5/2-B-VR //// B-VR = concrete pit with frame and sunken support beams including roller covers

- Model: TH 5/2-W-VR //// W-VR = trough pit with frame and sunken support beams including roller covers

| Cylinders | 2 |

| Capacity | 2 x 7,5t |

| Stroke | 1700mm |

| Piston Ø | 140/110 mm |

| Mounting depth | 1350mm |

| Frame length | 5000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 1,9m – max 4,0m |

| Art.-Nr. | 8.123.000 |

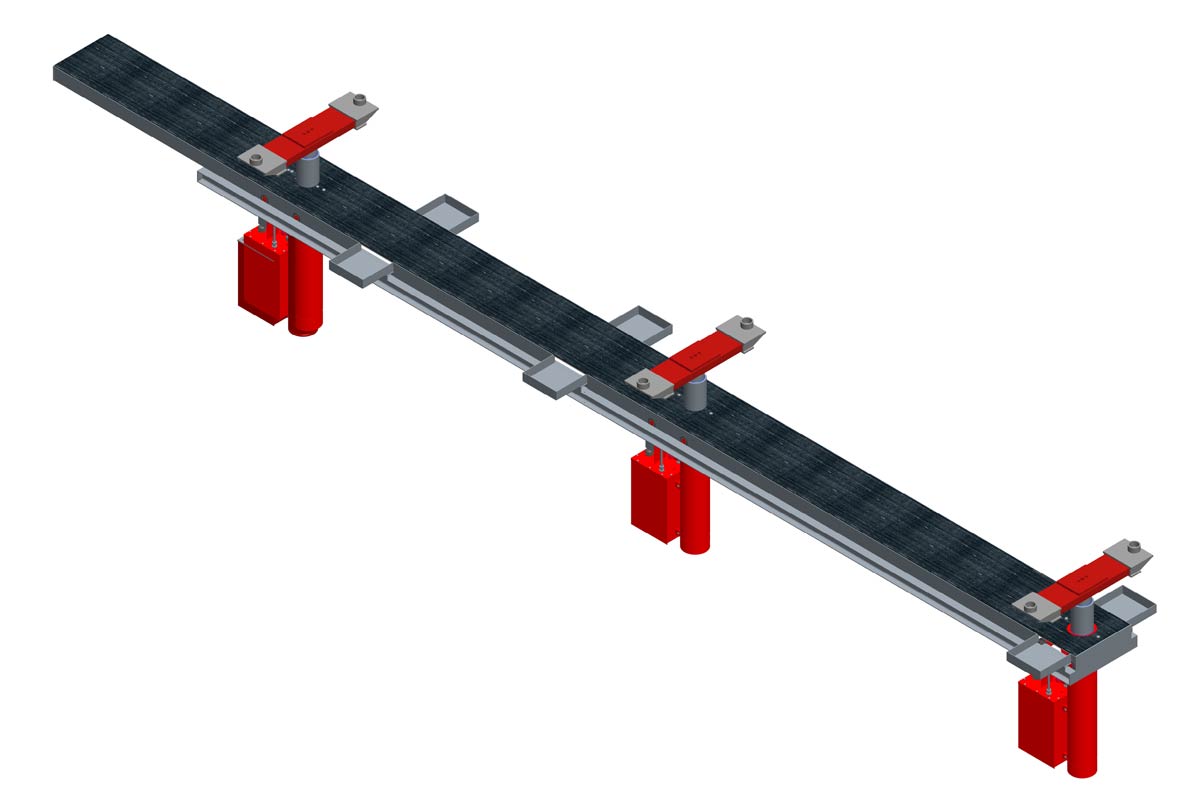

TH 10/2-B

- Model: TH 10/2-B //// B = concrete pit

- Model: TH 10/2-B-VR //// B-VR = concrete pit with frame and sunken support beams including roller covers

- Model: TH 10/2-W-VR //// W-VR = trough pit with frame and sunken support beams including roller covers

| Cylinders | 2 |

| Capacity | 2 x 14t |

| Stroke | 1700mm |

| Piston Ø | 171/140 mm |

| Mounting depth | 1350mm |

| Frame length | 7000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 2,5m – max 6,5m |

| Art.-Nr. | 8.125.000 |

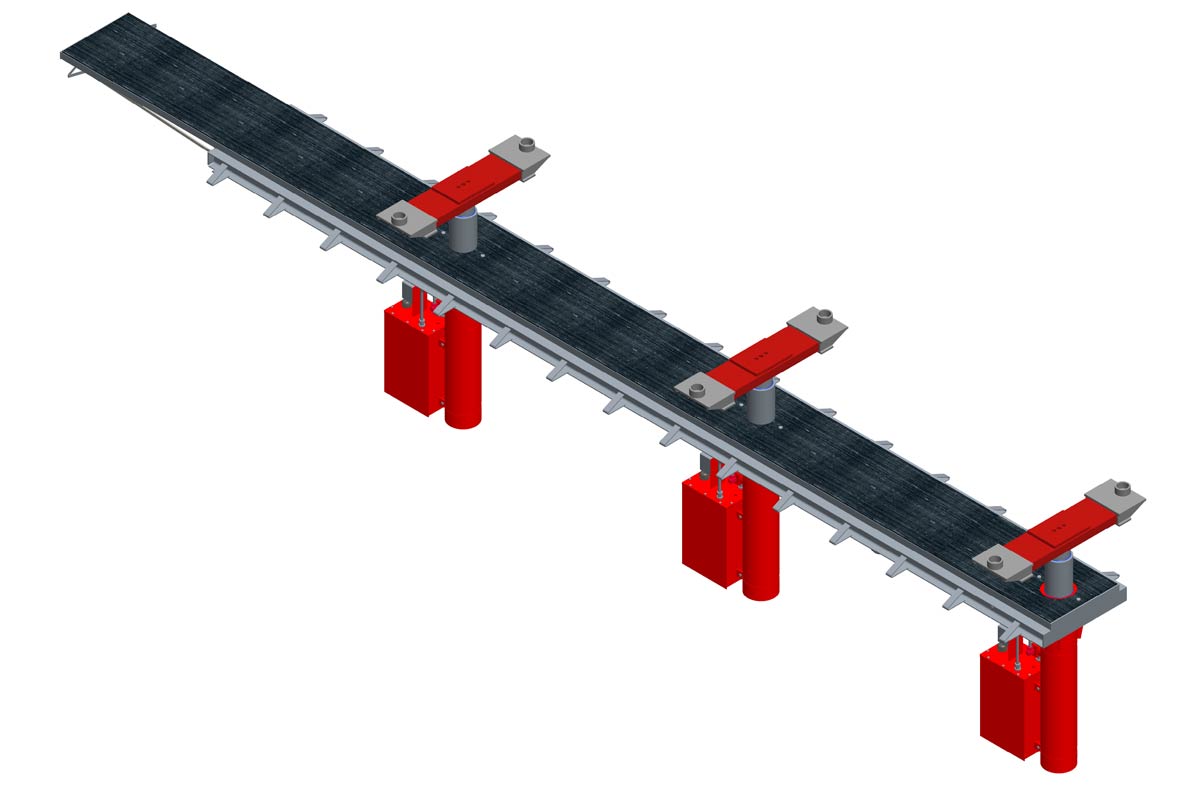

TH 10/3-B

- Model: TH 10/3-B //// B = concrete pit

- Model: TH 10/3-B-VR //// B-VR = concrete pit with frame and sunken support beams including roller covers

- Model: TH 10/3-W-VR //// W-VR = trough pit with frame and sunken support beams including roller covers

| Cylinders | 3 |

| Capacity | 3 x 14t |

| Stroke | 1700mm |

| Piston Ø | 171/140 mm |

| Mounting depth | 1350mm |

| Frame length | 7000mm (standard / custom lengths optionally available) |

| Positioning | Motorised |

| Adjustment range | min 2,5m – max 6,5m |

| Art.-Nr. | 8.195.007 |

Options

- Combination of units in one frame. Example: 4 cylinders 2+2 or 3+1

- Wash bay version (7m): axles, rollers, flashings and accessories galvanised, switch cabinet heated

- B = concrete pit

- W = trough version in the pit

- B-VR= concrete pit with frame and sunken support beams including roller covers

- W-VR= trough pit with frame and sunken support beams including roller covers

- Galvanised

- Telescopic cover 5t (15mm)

- Galvanised ground frame.

- Extensions to ground frames, covering and adjustment of the lift units

Datenblatt

Datenblatt